Engineering Tomorrow's Industrial Systems

Expert in Industrial Automation, Digital Twin Development, and Hardware-in-the-Loop Validation with hands-on experience in PLC systems, control engineering, and advanced simulation technologies.

Education & Technical Training

Strong academic background with specialized training in mechatronics and mechanical engineering

University of Huddersfield Sep 2022 - Sep 2023

MSc Mechatronics Engineering

Advanced studies in automation, robotics, control systems, and digital twin technology with practical applications in industrial systems.

• Specialized in Advanced Control Systems and Industrial Automation

• Thesis: "Integration of Digital Twin Technology in Industrial HVAC Systems"

• Gained expertise in MATLAB, Simulink, and simulation software

• Developed projects in robotics, IoT integration, and smart manufacturing

Indo German Tool Room (IGTR), Aurangabad 2016 - 2020

Bachelor of Engineering in Mechanical Engineering

Comprehensive foundation in mechanical engineering principles, thermodynamics, fluid mechanics, and precision engineering design with hands-on tool room training.

• Core courses: Thermodynamics, Fluid Mechanics, Machine Design, Manufacturing Processes

• Specialized training in precision tool design and manufacturing

• Workshops: CNC machining, CAD/CAM, precision measurement

• Project: Design and fabrication of specialized tooling systems

Technical Excellence

Specialized training in German precision engineering standards at Indo German Tool Room

My Engineering Journey

A snapshot of roles and accomplishments that showcase my engineering impact and growth.

Research & Development Engineer Aug 2023 – Aug 2024

Airedale by Modine

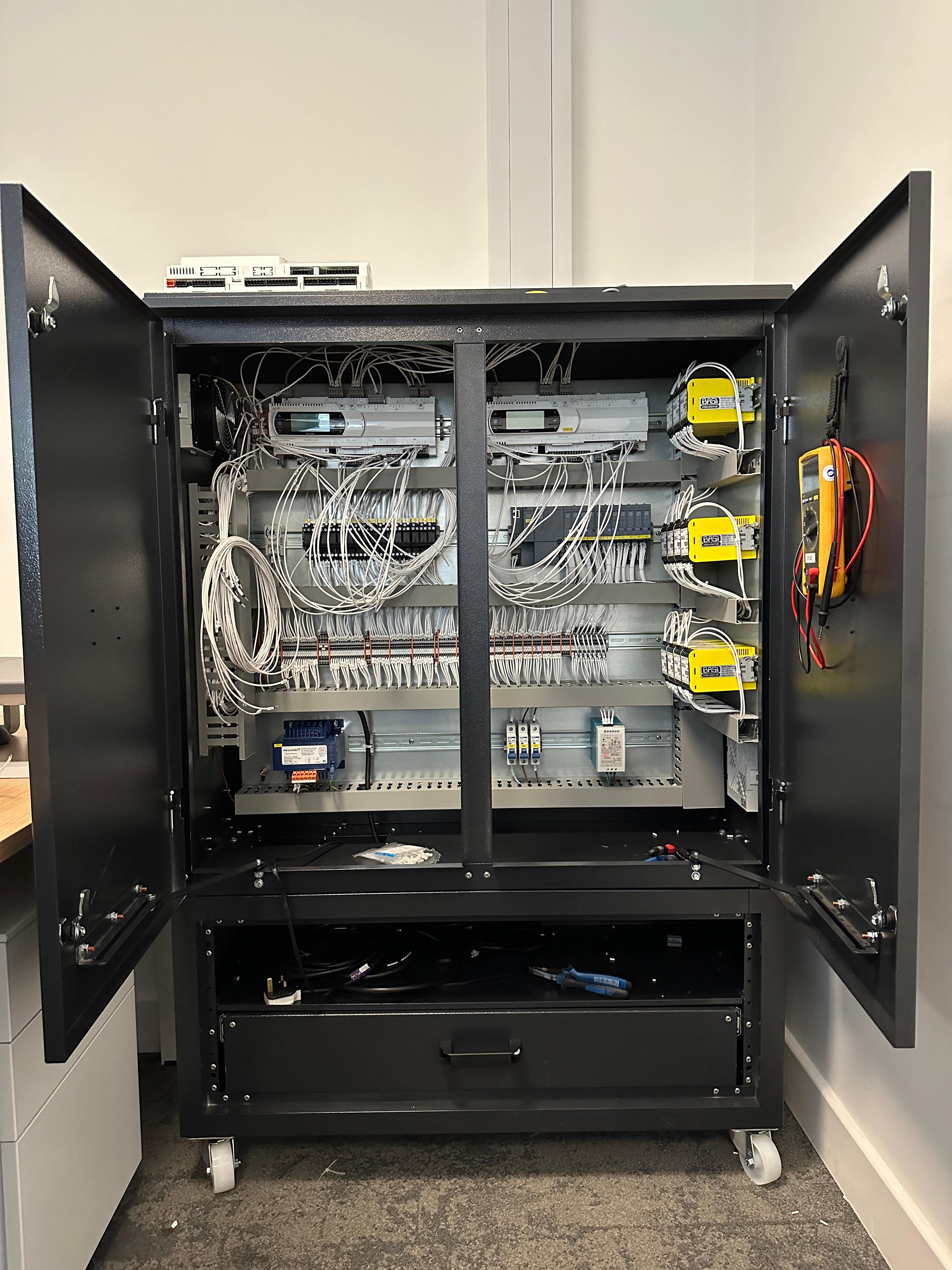

Drove the integration of digital‑twin technology with PLC systems for advanced HVAC applications. Developed hybrid simulation frameworks linking Siemens Simcenter models with real controllers to calibrate responses, tighten control loops and reduce validation time by 40%.

• Implemented hardware‑in‑the‑loop testing to validate PLC logic against virtual models

• Collaborated with cross‑functional teams to deploy a scalable digital‑twin platform

• Improved predictive maintenance accuracy by 30% through real‑time data analytics and root‑cause analysis

Junior Engineer Dec 2021 – Aug 2022

Forbes & Company Limited

Contributed to the assembly and commissioning of special‑purpose machinery and automation projects. Assisted senior engineers with PLC programming, sensor integration and system diagnostics to improve throughput and reliability.

• Assisted in PLC programming and troubleshooting for automated manufacturing lines

• Participated in installation and commissioning of special‑purpose machinery and robotics

• Contributed to safety protocol development and compliance documentation

• Provided hands‑on support for maintenance and process optimisation activities

Trainee Engineer Dec 2020 – Dec 2021

Forbes & Company Limited

Rotational trainee across design, production and automation teams. Built detailed CAD models, assisted in finite element analysis and supported tooling and manufacturing improvements.

• Developed 3D CAD models and prototypes for mechanical components

• Performed finite element analysis to validate design integrity

• Assisted in refining tooling and manufacturing processes to reduce material usage

• Supported cross‑functional teams on automation and control integration

Core Competencies

Specialized skills developed through academic excellence and hands-on engineering experience

Industrial Automation

PLC Systems, HIL Testing, Control Engineering

Expert in developing and implementing automation solutions for manufacturing and industrial processes with focus on reliability and efficiency.

Proficiency

Expert

Experience

4+ Years

Key Technologies: Siemens PLC, Allen-Bradley, Control Systems, HIL Testing

Applications: HVAC Automation, Manufacturing Lines, Process Control

Specialization: Digital Twin Integration, Predictive Maintenance Systems

Digital Twin & Simulation

Siemens Simcenter, Predictive Analytics, HIL

Advanced expertise in creating and implementing digital twin solutions for predictive maintenance and system validation.

Proficiency

Advanced

Impact

40% Efficiency Gain

Key Tools: Siemens Simcenter Amesim, MATLAB Simulink, 3D Modeling

Projects: Real-time HVAC Simulation, Predictive Maintenance Systems

Achievement: 40% reduction in validation time through HIL integration

Technical Analysis & Software

MATLAB, Python, Data Analysis, CAD

Proficient in engineering software, data analysis, algorithm development, and technical reporting for systems optimization.

Proficiency

Advanced

Tools

10+ Engineering Tools

Tools: MATLAB, Python, SolidWorks, AutoCAD, Data Visualization

Applications: System Performance Analysis, CAD Modeling, Optimization

Certification: Learning MATLAB by Majlinda Qarri, SolidWorks Associate

Featured Projects

Click on any project to explore detailed technical implementations and business impacts

Advanced HVAC Digital Twin System

Built a comprehensive digital‑twin solution by modelling HVAC systems in Siemens Simcenter Amesim and linking them with real PLC hardware. This enabled predictive maintenance, control loop calibration and accelerated validation cycles.

This project involved creating a real-time simulation environment that mirrored physical HVAC systems, allowing for predictive maintenance and reduced downtime. The system integrated Siemens Simcenter Amesim with PLC control systems through a custom Hardware-in-the-Loop interface.

Business Impact

• 40% reduction in validation time

• 25% improvement in predictive maintenance accuracy

• 30% decrease in system downtime

Industrial Automation Framework

As a Junior Engineer at Forbes & Company, I assembled and commissioned special‑purpose machinery and assisted with PLC programming. Working closely with senior engineers, I developed an automation framework that reduced manual intervention by integrating advanced PLC control systems and safety interlocks across multiple production lines.

This comprehensive automation solution involved programming PLC systems for multiple manufacturing lines, implementing safety interlocks, and creating a centralized monitoring system. The framework was designed to be scalable across different production environments.

Business Impact

• 60% reduction in manual intervention

• Improved safety compliance by 45%

• 15% increase in production throughput

Advanced CAD Design & Analysis

Developed complex mechanical designs and conducted structural analysis using CAD software for industrial applications.

This project involved creating detailed 3D models of mechanical components and assemblies, performing structural analysis, and optimizing designs for manufacturing. Worked on industrial machinery components, HVAC ducting systems, and custom fabrication designs using SolidWorks and AutoCAD.

Technical Innovation

• Reduced component weight by 15% through optimization

• Improved structural integrity by 25%

• Streamlined manufacturing processes

• Enhanced precision tooling designs

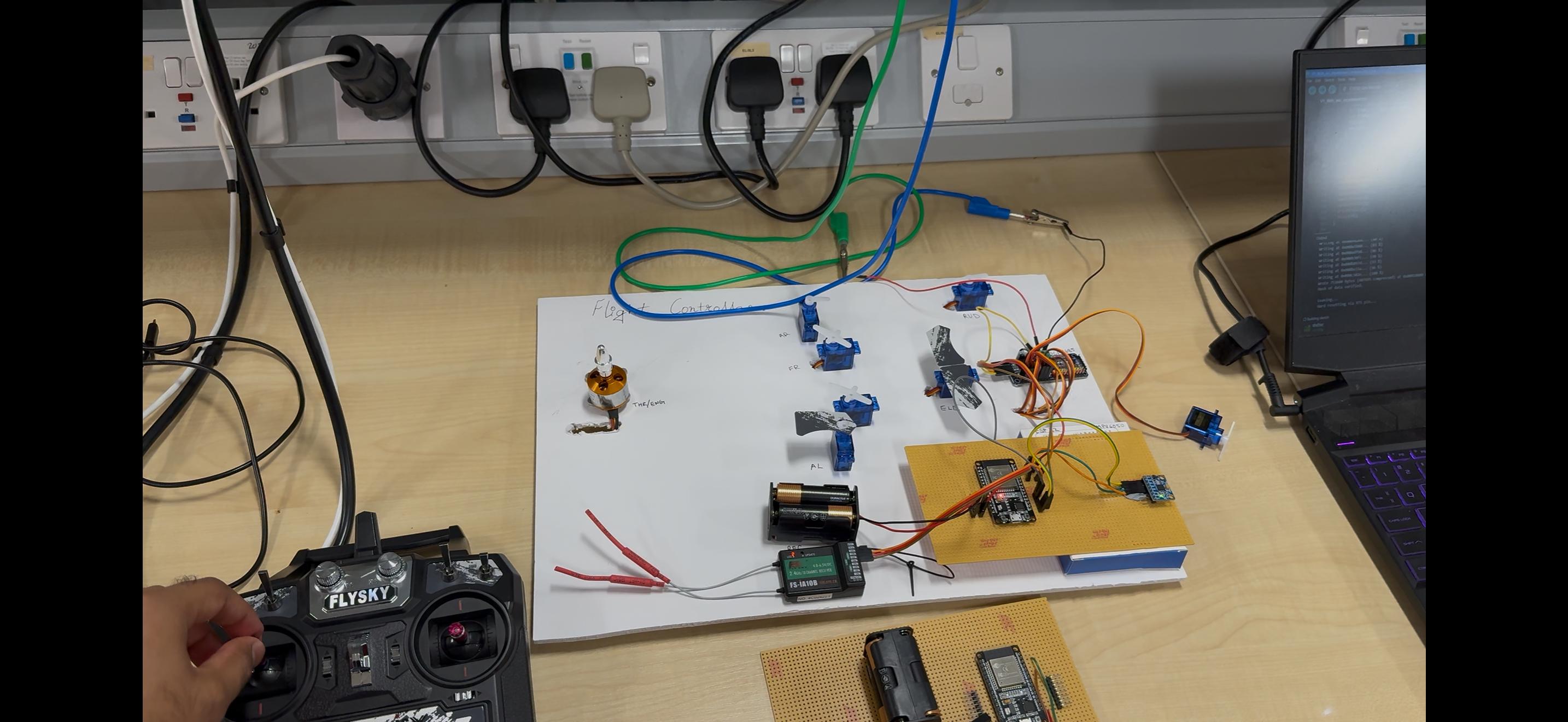

RC Flight Controller Prototype

Designed and implemented a flight‑control system for a highly manoeuvrable RC aircraft, treating it as a professional‑grade mechatronics project. The work combined embedded software, sensor fusion and servo actuation to deliver stable, repeatable flight behaviour and a flexible platform for future autonomy experiments.

Framed as a final‑year capstone but executed to industry standards, this project followed a full engineering lifecycle. I defined requirements, designed the system architecture (radio receiver, microcontroller, IMU, power distribution and servos) and implemented a PID‑based stabilisation and control‑mixing strategy. I built and wired the hardware, documented interfaces and test procedures, and validated the controller through bench tests and flight trials. The result was a robust, tunable controller that reduced pilot workload and demonstrated my ability to take a multidisciplinary system from concept to verified prototype.

Project Highlights

• Custom PID‑based flight stabilisation and mixing algorithm

• Integration of FlySky radio receiver with ESP32 microcontroller

• Construction of a fully wired servo rig and power distribution board

• Collaboration with industry partner Airedale by Modine for testing and validation

Mechatronics Engineer at a Glance

As a mechatronics engineer, I design, integrate and optimise smart systems that blend mechanics, electronics, control and software to deliver reliable automation solutions.

- System Design & Integration: Combine mechanical structures with sensors, actuators and controllers to create cohesive automated systems.

- Prototyping & Testing: Rapidly build and validate prototypes to ensure design reliability before scaling.

- Software & Programming: Develop PLC and microcontroller code to coordinate sensors and actuators.

- Sensor & Electronics Integration: Integrate diverse sensors, microcontrollers and electronics for accurate feedback and control.

- Automation & Robotics: Design and operate robotic systems and automated manufacturing cells.

- Troubleshooting & Maintenance: Diagnose system issues and implement preventative maintenance strategies.

- Project Management: Lead cross-functional teams, manage budgets and timelines, and ensure compliance with safety standards.

- Innovation & Research: Explore emerging technologies to drive continuous improvement and sustainable engineering.

Organisations I've Worked & Trained With

My engineering journey has been enriched by collaborating with leading companies, institutes and partners.

Who I Am

A glimpse into my background, education and passions outside of engineering.

I'm Jaydev Maosalkar, a mechatronics engineer with over three years of industrial experience in HVAC research and special‑purpose machinery. I specialise in digital‑twin modelling, PLC and controls engineering, and hardware‑in‑the‑loop validation. My recent work includes building Siemens Simcenter Amesim models linked with PLCs to calibrate real‑time responses, tighten control loops and de‑risk shop‑floor testing through structured root‑cause analysis and clear technical reports for stakeholders.

I'm motivated by roles where digital twins, controls engineering and data‑informed validation improve reliability, energy efficiency and throughput across HVAC, manufacturing and industrial automation. With a BEng (Hons) in Mechatronics from the University of Huddersfield and specialised training at Indo‑German Tool Room, I look forward to applying my skills to complex engineering challenges and delivering efficient, sustainable systems.